What defines the price of a corrugated box?

Corrugated Boxes are highly customizable. Many factors go into making the right corrugated box for your product which ultimately affects its performance, weight and cost.

Type of Paper

One of the essential factors that define the properties of the corrugated box is the type of paper used.

There are mainly two types of paper that are generally used for liners: Kraft and Duplex.

- Kraft paper is the most commonly used outside liner for corrugated boxes. It is manufactured from softwood trees. Due to the “virgin fibres”, It is the most potent form of paper. It is the most common outside liner for corrugated boxes.

- Duplex is a double-layered paper. It is either bleached on one side (Grey Back) or both sides (white back). It is made entirely out of recycled. It is used mainly as the outside liner since it provides an excellent base for colour printing.

Each liner type is composed of two layers. A primary layer is used to provide adhesion and strength while another finer ‘cover’ layer is used to improve aesthetics and to aid printing.

Though these two types are the most popular type of paper used in the corrugated boxes, there are other multiple variants available in the market.

Paper Weight

Having understood the types of papers that are used for corrugated boxes, it is also essential to consider the weight. The standard measurement unit used throughout the packaging industry is Grams per Square Meter (GSM). Higher the GSM, higher will be the bursting strength of the paper.

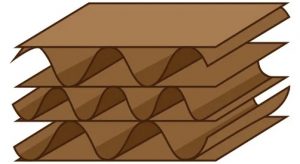

Wall Types

Apart from the varying paper type and weight, the number of fluting (wall types) must also be considered.

As mentioned, all corrugated boards have a layer of corrugated fluting and at least one-liner.

| A board with a layer of corrugated fluting and two liners is called a Single Wall or 3 Ply Board. It is the most common type of corrugated board. |  |

| Adding an additional layer of flute and liner to single wallboard gives us a Double Wall or 5 Ply Board. It effectively provides extra rigidity and strength to the board and is suitable for packing heavier items. |  |

| A Triple or 7 Ply Board has three layers of fluting which make the corrugated board a dependable choice for shipping items that need special handling. |  |

| Next up is the width of the flute. |

Flute profile

Flutes serve as a protective cushioning and help in strengthening a carton. Different widths and configurations offer distinctive performance advantages. Commonly used flute are B, C, E and F of which C-Flute is used in more than 80% of the corrugated boxes.

| B-Flute= With a thickness of around 3mm, this flute type offers excellent crush and puncture resistance. It is exceptionally versatile and can be used in both die-cutting and regular case-making processes. |  |

| C-Flute= With a thickness of around 4mm, this flute types offers good printing surface and greater compression strength. This means it provides better stacking strength and is commonly used for shipping boxes and to secure glass, furniture, food, etc. |  |

| E-Flute= With a thickness of around 1.5mm, this flute type not only offers excellent compression strength and crush resistance but also means it provides a high-quality surface for printing. Consequently, it is commonly used in smaller cartons, where the excellent quality print is required, plus die cutting applications. |  |

| F-Flute= With a thickness of around 0.8mm, this flute type has an outstanding printing surface and excellent crush resistance. This type is commonly used in fast food clamshell containers and packaging for mobile phones, cosmetics etc. |  |