Infrastructure

With dedicated pre-press, press, post-press and corrugation department under one roof, ensuring vertical synergy, HSM provides its customers with a one-stop solution to a wide range of their paper packaging needs.

Pre-Press

Our in-house graphic designer and plate making department ensures timely initiation of the printing process.

We are equipped with a Polar Paper Cutter which facilitates the pre-press process.

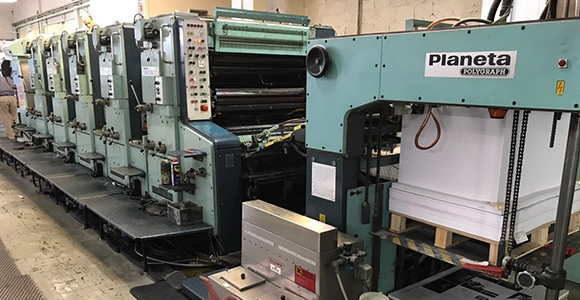

Press

Our printing capabilities strengthens with the availability of 1/4/5/6 colour sheet-fed offset types of machinery printing up to the size of 44″ x 64″.

Post-press

Our fleet of 5 die-cutting machines with a maximum size of 52″ x 72″ and an Automatic die-cutting machine of size 37*52 supports us to meet varied types of client requirements.

We are also equipped with Advanced Rotary Slotter, Eyeleting, Side Pasting, Aqueous Coater, Stapling and Lamination machines.

Corrugation

The corrugation department is equipped with a fleet of 4 corrugation machines with a maximum size of 62″. This makes us well-positioned to support a wide range of corrugation requirements and manufacture B, C and E and F type of flutes.